No low-effort one-liner comments, memes, or off-topic replies. Answers must contain an explanation using engineering logic, and assertions of fact must be supported by links to credible sources.īe substantive. Racism, sexism, or any other form of bigotry will not be tolerated.ĭon't answer if you aren't knowledgeable. All users are expected to behave with courtesy. Mechanical, Electrical, Civil, Chemical, and Computer are reserved for technical questions only.Ĭareer must be used for all questions on career advice, salary, job market, etc.ĭiscussion can be used for general questions that apply to multiple disciplines, including some workplace topics.īe respectful to other users. Remember to flair your post.Īvoid questions that can easily be answered by searching on the internet. Post titles must be a question about engineering and provide context - be specific. By practicing on a virtual system, users will learn to perform quicker diagnostics and troubleshooting, which will in time help reduce maintenance costs.Īutomation Studio 6.Call for Engineers: Tell us about your job! (2020) New to AskEngineers? Read our subreddit rules and FAQ page before posting! Topic Filters ⇨ Exclude All Career Posts

Its uses include its programming for CAD, maintenance and other. It has many uses and it is special software. The electrical projects apprehended from Famic Technologies Inc.

#AUTOMATION STUDIO 6 SOFTWARE#

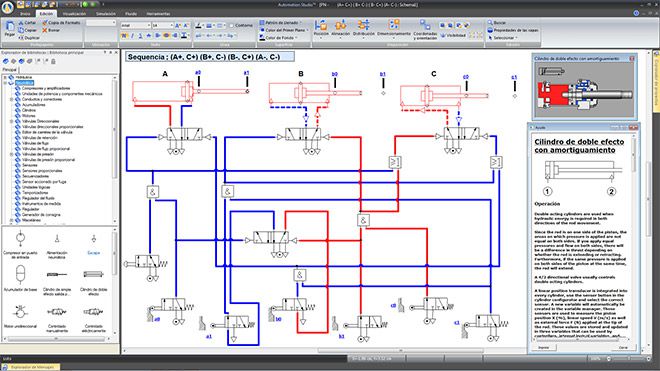

It is also used as a simulation and project documentation software for Fluid Power systems. Automation Studio can also communicate with any CAN bus J1939 devices either to test a controller’s algorithm with a complete virtual machine, or to create a realistic and cost effective training environment. Automation Studio is a circuit designing software. Users can therefore create a model-in-the-loop (MIL) testing environment using APIs to simulate multi-technology systems modeled in Automation Studio with other complementary multi-physics simulation software. In this experiment, we evaluate the recognition performance of AV recognition system under.

Version 6.3 of Automation Studio additionally expands its co-simulation reach with other platforms. The JM studio 6 is used to transmit and receive the data. Multi-user, multi-language and remote access. Famic Technologies announces the launch of Automation Studio 6.3, a system design, simulation, documentation, training and maintenance software for the fluid power, electrical and automation fields. Co-simulation via CANbus to create a realistic training environment with Automation Studio 6.3. Famic Technologies has released Automation Studio 6.3, an all-in-one design and simulation software. Additionally, Filter, Sort and Group features are available to help intuitively find the desired information. Added features in the software allow users to edit component properties included in the schematics directly from the reports. Users can generate automatically Bills of Materials and reports by using their own template or by choosing and customizing existing ones. The automatic documentation features offered in Automation Studio will help users produce quickly and easily various documents, to help increase productivity and reduce machine time to market. Version 6.3 of Automation Studio enhances machine documentation capabilities and offers users moreįlexibility with its new BOM & Report Module. Automatic documentation and reports can then be generated directly from the schematics to ensure proper machine documentation. Products to create intelligent 2D schematics, and analyze the system’s behavior in simulation mode to help save time in prototyping phase and prevent faults at an early stage in design. The user can drag-and-drop pre-configured components from the library or select virtual manufacturers’ It allows users to easily combine these various technologies in order to design, document and validate complete systems using simulation.Ĭo-simulation capabilities with Automation Studio 6.3 by CANbus J1939 and by API.

Hydraulics, pneumatics, electrical, controls, HMI and communications. Version 6.3 of Automation Studio better supports users’ documentation needs by offering a new environment of its BOM & Report Module, and expands its co-simulation reach with third-party software, control devices and PLCs.Īutomation Studio is a unique software solution covering all project/machine technologies including

Famic Technologies has released the latest version of Automation Studio, its machine design and simulation software.

0 kommentar(er)

0 kommentar(er)